Executive Summary

A leading global manufacturing enterprise sought to modernize its fragmented order fulfillment operations, which spanned disconnected sales, production, inventory, and logistics systems. Manual order validation, delayed production scheduling, inventory visibility gaps, and siloed coordination led to fulfillment delays, stockouts, excess inventory costs, and poor customer satisfaction.

To overcome these barriers, the organization implemented an AI-driven Manufacturing & Fulfillment Multi-Agent Platform built on AWS.

The solution unified ERP, production, inventory, and logistics systems under an intelligent orchestration layer, enabling autonomous decision-making across demand forecasting, inventory control, production planning, warehouse operations, and supply chain procurement.

Customer Challenge

Customer Information

-

Customer: Confidential Global Manufacturing Enterprise

-

Industry: Manufacturing and Industrial Production

-

Location: Confidential

-

Company Size: Global enterprise with multiple production facilities

Business Challenges

-

Fragmented visibility across sales, production, inventory, and warehouse operations

-

Inefficient production scheduling without real-time capacity and material constraints

-

Delayed material procurement lacking supplier intelligence and cost optimization

-

Siloed communication between sales, production, warehouse, and procurement teams

-

Rising operational costs from inefficiencies, delayed deliveries, and manual coordination

Technical Challenges

-

Disparate data sources (SAP ERP, Oracle, legacy MES systems)

-

No unified platform for real-time order-to-delivery orchestration

-

Manual data extraction and reconciliation between systems

-

Lack of real-time inventory visibility across finished goods, raw materials, and WIP

-

No predictive capabilities for demand forecasting or production optimization

-

Limited integration capabilities across multi-location operations

Partner Solution

Solution Overview

The enterprise implemented the Manufacturing & Fulfillment Multi-Agent Platform on AWS as an AI-native multi-agent solution for end-to-end order fulfillment optimization. The solution functions as a centralized AI orchestration layer deployed within an Amazon EKS cluster, where specialized agents handle domain-specific functions and communicate via Agent-to-Agent (A2A) protocol.

Built on LangGraph orchestration framework, the solution integrates real-time data from ERP, SAP, Oracle, and logistics systems through Model Context Protocol (MCP) enabled connectors, delivering actionable insights across the complete order-to-delivery lifecycle.

Key Components

-

Orchestrator Agent – Centralized workflow controller

-

Demand Forecasting Agent – Validates order feasibility against current capacity and inventory.

-

Inventory Control Agent – Monitors real-time stock levels of finished goods, raw materials.

-

Production Planning Agent – Creates optimized production schedules considering machine capacity, labor availability.

-

Warehouse & Fulfillment Agent – Manages storage optimization, packaging workflows, and dispatch coordination.

-

Supply Chain Management Agent – Sources and procures raw materials from optimal suppliers

-

MCP Servers – Provide standardized access to SAP, Oracle ERP, logistics providers, and MS Teams for seamless integration

-

Bedrock Integration – Manages foundation models (Claude, Nova series), prompt governance, and compliance guardrails for intelligent decision-making

AWS Services Used

-

Amazon EKS – Containerized agent deployment and orchestration with managed scaling

-

Amazon Bedrock – Foundation models for reasoning, feasibility analysis, and optimization

-

Bedrock Prompt Management – Centralized prompt governance and version control

-

Bedrock Guardrails – Model safety and compliance enforcement

-

Aurora PostgreSQL – Central data store for orders, inventory, schedules, and supplier data

-

Amazon S3 – Knowledge base storage (BOMs, supplier catalogs, historical data)

-

Amazon CloudWatch / Metrics Insights / Alarms – Monitoring, alerts, and performance tracking

-

Amazon Route 53 – DNS routing and load distribution

-

Network Load Balancer – Traffic distribution within secure VPC

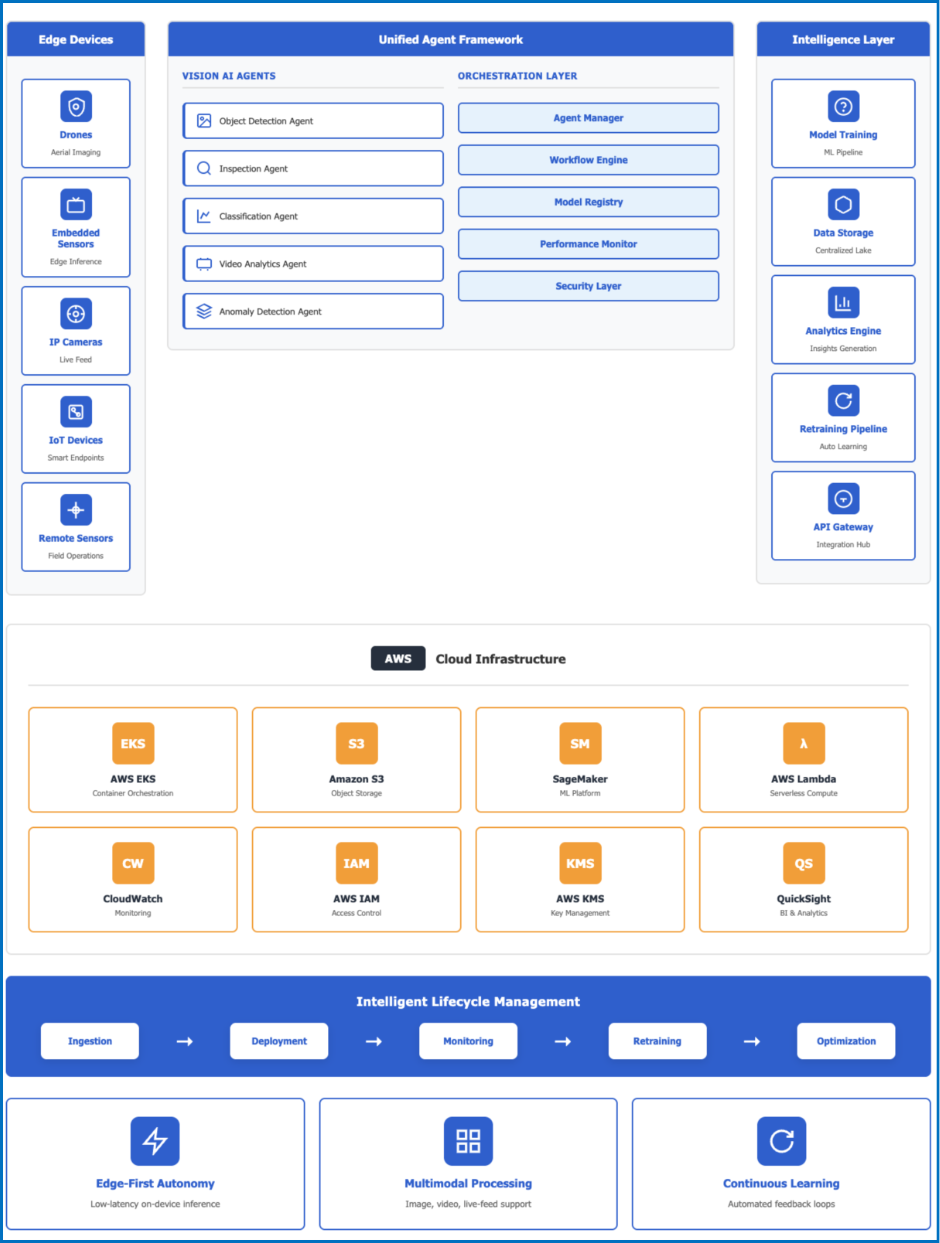

Architecture Diagram

Implementation Details

-

Adopted a phased rollout, starting with order validation and inventory modules, followed by production planning and warehouse operations

-

Deployed microservices and AI agents on Amazon EKS within isolated namespaces for scalable, modular architecture

-

Integrated ERP systems (SAP, Oracle) via MCP-enabled connectors for standardized, low-latency access to inventory and production data

-

Implemented LangGraph orchestration framework for visual graph-based workflow management and multi-agent coordination

-

Enabled Agent-to-Agent (A2A) protocol for concurrent agent tasking and parallel execution

-

Deployed Demand Forecasting Agent to validate real-time order feasibility against capacity and inventory from SAP/Oracle

-

Trained Production Planning Agent on historical production cycles, machine capacity, and resource constraints

-

Deployed Amazon CloudWatch alarms for monitoring agent performance, order processing times, API latency, inventory levels, and system health

Innovation and Best Practices

-

Introduced AI-driven order feasibility validation reducing validation time

-

Implemented Model Context Protocol (MCP) for standardized ERP and logistics integration, reducing integration complexity

-

Used Amazon Bedrock Guardrails for ensuring AI safety, compliance, and policy enforcement across all agent interactions

-

Implemented phased delivery coordination for large orders, enabling immediate partial shipment of available inventory

-

Enabled real-time inventory synchronization across multiple warehouses and production facilities

-

Integrated MS Teams and Enterprise Portal for conversational AI interaction, order tracking, and collaborative workflow management

-

Established VPC endpoints for private connectivity without internet exposure

-

Used KMS encryption for data at rest and TLS 1.3 for data in transit

-

Implemented intelligent supplier selection based on historical performance, cost optimization, and lead time analysis

Results and Benefits

Business Outcomes and Success Metrics

-

Significant reduction in order fulfillment time with streamlined workflows from order receipt to final delivery

-

Substantial decrease in operational costs through automated coordination and elimination of manual processes

-

Major reduction in inventory carrying costs through intelligent stock management and just-in-time production principles

-

Dramatic improvement in on-time delivery performance exceeding industry benchmarks

-

Considerable reduction in stockout incidents through predictive monitoring and automated procurement triggers

-

Notable improvement in customer satisfaction scores via proactive communication and accurate delivery timelines

-

Accelerated order validation process from hours to seconds, enabling instant customer feedback

Technical Benefits

-

Centralized intelligence layer across heterogeneous manufacturing systems

-

Real-time order-to-delivery visibility across all operations

-

Modular agent design simplified maintenance and scaling

-

Improved system resilience with EKS and VPC isolation

-

Seamless integration with SAP, Oracle, logistics APIs, and MS Teams

-

AI-powered production scheduling reduced manual planning time by 90%

-

Full auditability and traceability via Aurora PostgreSQL and CloudWatch

Customer Testimonial

Confidential

Lessons Learned

Challenges Overcome

-

Complex integration with multiple legacy ERP systems requiring custom MCP connectors for production data.

-

Data normalization across different formats, schemas, and regional manufacturing facilities.

-

Aligning AI agent outputs with existing production approval workflows and human oversight requirements.

-

Managing organizational change across globally distributed operations, procurement, and warehouse teams.

-

Ensuring data consistency between real-time inventory updates and batch production schedules.

-

Coordinating phased deliveries across multiple warehouses and logistics providers.

Best Practices Identified

During the implementation, the following best practices emerged as critical success factors:

-

Data Foundation First: Establishing a robust data governance framework proved essential for ensuring consistent inventory tagging, SKU standardization.

-

Incremental Value Delivery: A modular, phased rollout approach starting with order validation before expanding production planning demonstrated measurable value at each stage, building organizational confidence and momentum for broader adoption.

-

Clear Human-AI Boundaries: Defining explicit approval of workflows and decision boundaries between automated agent actions and human oversight requirements helped balance efficiency gains with appropriate governance and control.

-

Early Integration Standardization: Implementing Model Context Protocol (MCP) standardization at the project outset significantly simplified multi-system integration complexity with SAP, Oracle, and logistics providers, reducing technical debt.

-

Comprehensive Observability: Investing detailed monitoring infrastructure from day one enabled rapid identification of performance issues, agent behavior analysis through CloudWatch metrics and logging.

-

Transparent AI Reasoning: Documenting and exposing agent decision-making paths proved valuable for building trust, supporting compliance audits, troubleshooting edge cases, and enabling continuous improvement feedback loops.

Future Plans

-

Extend platform to multi-cloud visibility (Azure, GCP) for global operations

-

Integrate predictive maintenance for production equipment to prevent downtime

-

Introduce autonomous procurement execution for low-risk, repetitive material orders

-

Implement quality control agent for automated defect detection and root cause analysis

-

Expand sustainability tracking for carbon-aware production and logistics optimization

-

Deploy returns management agent for automated reverse logistics

-

Integrate customer portal for self-service order tracking and delivery management

-

Explore Amazon Neptune ML for advanced supply chain network optimization

-

Implement digital twin simulation for production scenario planning

-

Add IoT integration for real-time machine and inventory sensor data

Next Steps

Discover how compound AI systems and agentic workflows can transform your order‑to‑delivery operations. We’ll show you how manufacturing leaders are using multi‑agent orchestration on AWS to automate tasks, streamline decision making, and optimize IT support and operations—helping every department become decision‑centric, improve efficiency, and enhance responsiveness across the supply chain.