Executive Summary

A leading global manufacturing enterprise sought to modernize its fragmented procurement ecosystem, which spanned multiple ERP and supply chain systems. Manual approval cycles, delayed supplier insights, and disconnected logistics workflows led to inefficiencies, higher sourcing costs, and limited visibility across operations.

To overcome these barriers, the organization implemented an AI-driven Multi-Agent Procurement Platform built on AWS.

The agent unified ERP, procurement, and logistics systems under an intelligent orchestration layer , enabling autonomous decision-making across inventory management, demand forecasting, logistics optimization, procurement and risk governance. It also introduced automated RFQ (Request for Quotation) document creation and management, where procurement agent analyzes needs, identify suitable suppliers, generate standardized RFQs, and route them for approval and dispatch.

Customer Challenge

Customer Information

-

Customer: Confidential Global Manufacturing Enterprise

-

Industry: Manufacturing and Industrial Production

-

Location: Location

-

Company Size: Global enterprise

Business Challenges

-

Fragmented supply chain visibility across plants, warehouses, and suppliers

-

Delayed insights due to siloed ERP and logistics systems

-

Manual risk detection for production and logistics bottlenecks

-

Lack of predictive analytics for demand fluctuations

-

Limited collaboration between procurement, operations, and logistics teams

-

Rising costs from inefficiencies, stockouts, and overproduction

Technical Challenges

-

Disparate data sources (SAP, Oracle ERP, MES)

-

No unified platform for data correlation and decision-making

-

Manual data extraction and reconciliation between systems

-

Lack of real-time inventory checks, supplier and shipment status tracking

-

Complex integration requirements across multi-cloud environments

-

Limited AI/ML maturity for predictive supply chain insights

The organisation needed an AI-native procurement platform to unify its ecosystem, automate repetitive tasks like RFQ creation, and drive real-time, data-driven decision-making across global operations.

Partner Solution

Solution Overview

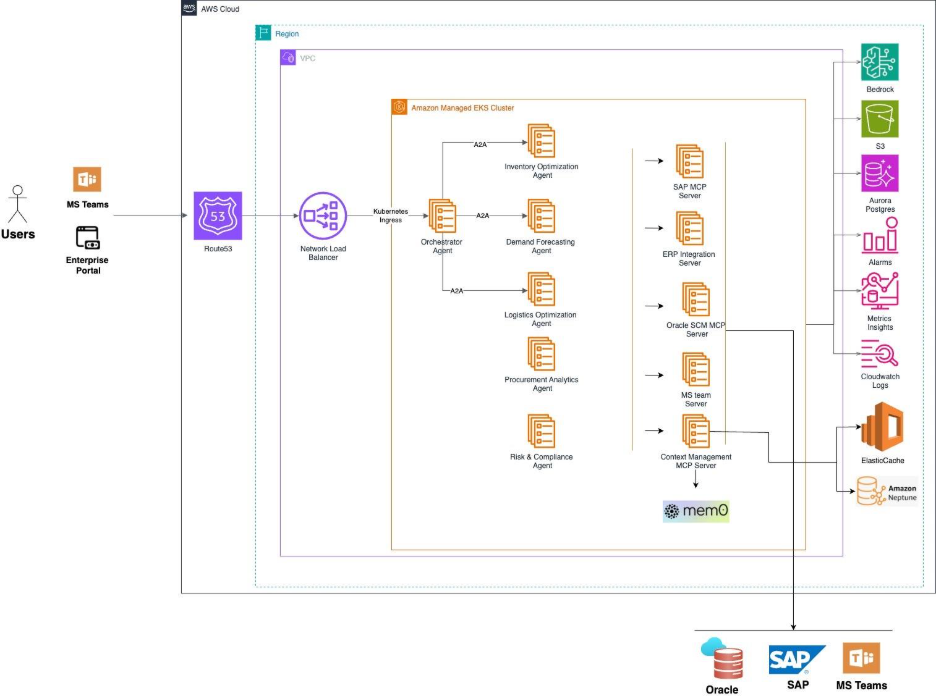

The enterprise implemented the Multi Agent Procurement Platform on AWS as an AI-native multi-agent platform for end-to-end supply chain optimization. The solution functions as a centralized AI orchestration layer deployed within an Amazon EKS cluster, where specialized agents handle domain-specific functions and communicate via Agent-to-Agent (A2A) protocol.

Built on powerful orchestration framework, the agent integrates real-time data from ERP, SAP, Oracle SCM, and procurement systems through Model Context Protocol (MCP) enabled connectors, delivering actionable insights across the complete supply chain lifecycle.

Key Components

-

Orchestrator Agent – Centralized workflow controller that analyzes user intent, decomposes requests into agent-level tasks, and coordinates execution across specialized agents

-

Inventory Optimization Agent – Balances stock levels across production and distribution centers, queries real-time inventory via MCP to SAP/Oracle, and prevents shortages and overstock situations

-

Demand Forecasting Agent – Predicts demand using historical sales data, seasonality patterns, and macro trends through Bedrock-powered time-series analysis

-

Logistics Optimization Agent – Enhances shipment routing, delivery schedules, and cost efficiency through AI-driven route optimization

-

Procurement Analytics Agent – Analyzes supplier performance, purchase cycles, and sourcing costs. Generates automated RFQs with embedded details (part specifications, quantities, SLAs) based on inventory levels and demand forecasts

-

Risk & Compliance Agent – Detects operational, financial, and regulatory risks in real-time, monitors SLA breaches, and ensures policy enforcement

-

MCP Servers – Provide standardized access to SAP, Oracle SCM, ERP systems, and MS Teams for seamless integration

-

Context Management Layer – Provides persistent memory, semantic recall, and knowledge graphs using Redis and Neptune

-

Bedrock Integration – Manages foundation models (Claude, Nova series), prompt governance, and compliance guardrails

AWS Services Used

-

Amazon EKS – Containerized agent deployment and orchestration with managed scaling

-

Amazon Bedrock – Foundation models for reasoning, forecasting, and summarization

-

Bedrock Prompt Management – Centralized prompt governance and version control

-

Bedrock Guardrails – Model safety and compliance enforcement

-

Aurora PostgreSQL – Central data store for supply chain metrics and recommendations

-

Amazon ElasticCache (Redis) – Short-term agent memory and caching

-

Amazon Neptune – Knowledge graph of suppliers, logistics routes, and inventory nodes

-

Amazon CloudWatch / Metrics Insights / Alarms – Monitoring, alerts, and performance tracking

-

Amazon Route 53 – DNS routing and load distribution

-

Network Load Balancer – Traffic distribution within secure VPC

Architecture Diagram

Implementation Details

-

Adopted a phased rollout, starting with inventory optimization and procurement modules, followed by demand forecasting and logistics optimization

-

Deployed microservices and AI agents on Amazon EKS within isolated namespaces for scalable, modular architecture

-

Integrated ERP systems (SAP, Oracle) via MCP-enabled connectors for standardized, low-latency access

-

Implemented orchestration framework for visual graph-based workflow management and multi-agent coordination

-

Enabled Agent-to-Agent (A2A) protocol for concurrent agent tasking and parallel execution

-

Deployed Inventory Optimization Agent to validate real-time stock levels from SAP.

-

Trained Demand Forecasting Agent on historical sales, seasonality, and external market data.

-

Configured Procurement Analytics Agent to auto-generate structured RFQs based on inventory gaps, supplier performance, cost variance, and lead times

-

Implemented Risk & Compliance Agent for anomaly detection in raw material costs and delayed vendor shipments

-

Configured Amazon CloudWatch alarms for monitoring agent performance, RFQ cycle times, API latency, and system health

Innovation and Best Practices

-

Introduced AI-driven predictive analytics for demand forecasting

-

Implemented Model Context Protocol (MCP) for standardized ERP and SCM integration, reducing integration complexity

-

Automated RFQ generation and supplier selection based on performance metrics, cost analysis, and compliance requirements

-

Used Amazon Bedrock Guardrails for ensuring AI safety, compliance, and policy enforcement across all agent interactions

-

Implemented graph-based dependency modeling with Neptune to identify supply chain bottlenecks

-

Enabled cross-functional visibility across procurement, operations, and logistics through unified dashboards

-

Integrated MS Teams for conversational AI interaction and collaborative workflow management

-

Established VPC endpoints for private connectivity without internet exposure

-

Used KMS encryption for data at rest and TLS 1.3 for data in transit

Results and Benefits

Business Outcomes

-

Significant improvement in demand forecast accuracy through Bedrock-powered predictive modeling

-

Noticeable reduction in logistics and procurement costs through AI-driven optimization

-

Enhanced end-to-end supply chain visibility across all interconnected systems

-

Lower inventory holding costs through balanced and adaptive stock management

-

Accelerated RFQ generation and supplier response cycles

-

Faster response to risk alerts and production variances

-

Stronger supplier performance tracking and compliance monitoring

Technical Benefits

-

Centralized intelligence layer across heterogeneous systems

-

Real-time insights through streaming and IoT integration

-

Modular agent design simplified maintenance and scaling

-

Improved system resilience with EKS and VPC isolation

-

Seamless integration with ERP, MES, and logistics APIs

-

AI-powered recommendations reduced manual intervention

-

Full auditability and traceability via Aurora PostgreSQL and CloudWatch

Customer Testimonial

Confidential

Lessons Learned

Challenges Overcome

-

Complex integration with multiple legacy ERP requiring custom MCP connectors

-

Data normalization across different formats, schemas, and regional systems

-

Aligning AI agent outputs with human decision-making processes and approval workflows

-

Managing organizational change across globally distributed procurement and operations teams

-

Ensuring data consistency and quality across real-time and batch data sources

-

Balancing automation with human oversight for critical procurement decisions

Best Practices

-

Begin with data governance framework to ensure consistent tagging.

-

Focus on modular, phased rollouts to demonstrate incremental value.

-

Establish clear approval workflows defining boundaries.

-

Implement MCP standardization early to simplify multi-system integration.

-

Enable self-service dashboards using QuickSight for stakeholder empowerment and transparency

-

Invest in comprehensive monitoring with CloudWatch.

Document agent reasoning paths for transparency and compliance auditing

Future Plans ( if any)

-

Extend platform to multi-cloud visibility (Azure, GCP).

-

Integrate sustainability tracking for carbon-aware logistics.

-

Introduce autonomous procurement execution for low-risk items.

-

Expand predictive maintenance for IoT-connected assets.

-

Explore Amazon Neptune for supply chain graph analytics.

Next Steps

Talk to our experts about transforming procurement and supply chain operations with AI-driven multi-agent intelligence on AWS. Discover how enterprises leverage Agentic Workflows and Decision Intelligence to automate sourcing, optimize logistics, and enable data-driven procurement — enhancing efficiency, agility, and end-to-end visibility across manufacturing ecosystems.

.png)